|

February 2018

Musculoskeletal injury (MSI) risk controls Musculoskeletal injury (MSI) risk controls

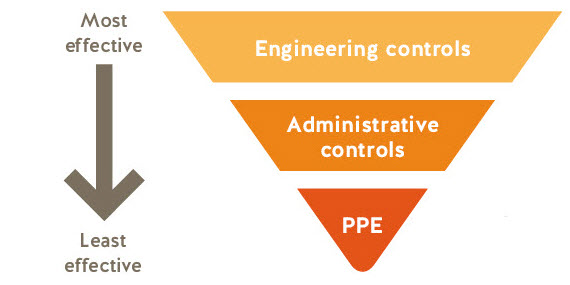

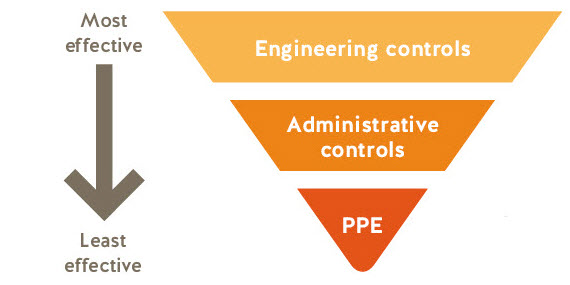

MSI risks exist in every workplace, whether it’s an office or a manufacturing facility. These risks include awkward postures, static postures, repetition, and force. Fortunately, implementing engineering and administrative controls can help reduce the risk of MSI.

Engineering controls are physical modifications to a job or job task. For example:

- Implementing lifting devices for heavy manual material handling tasks

- Reducing the weight of an object to reduce the force needed to lift it (e.g., changing the product design)

- Substituting different tools and equipment to minimize awkward or static postures

- Redesigning a workstation to minimize the need for excessive reaching

Administrative controls are management-directed work practices and policies designed to reduce or prevent exposure to risks. For example:

- Developing standard operating procedures and providing workers with appropriate training for them

- Creating lifting policies that include minimal manual material handling

- Providing workers with training on ergonomic best practices and work methods

- Providing workers with training on MSI risks and how to prevent them

- Establishing policies for using and maintaining tools and equipment safely

- Introducing job rotation

Although engineering controls are generally more effective than administrative controls for reducing the risk of injury, the best approach is to consider both. If you’re implementing the use of a new tool (an engineering control), for example, you should also develop training and policy (administrative controls) to ensure the tool works as intended.

Does job rotation prevent MSI?

Overexposure to one type of movement can lead to injury. Implementing job or task rotation is an administrative control that can help reduce the risk. The general principle behind job rotation is that rotating work allows fatigued muscle groups to recuperate while other muscles perform work.

Although job rotation has some associated risks, it has many benefits.

Risks:

- There may be some confusion with scheduling as well as complaints from workers. Changes in the workplace often evoke resistance.

- Employees may initially experience discomfort due to engaging muscles they don’t normally use.

- Some rotations may not be true job rotations. Moving a worker to a similar task may result in the same exposure.

Benefits:

- Reduces worker exposure to the physical demands of one task

- Ensures different muscle groups are used

- Decreases fatigue in one muscle group

- Minimizes the amount of time a worker is exposed to a maximum weight, repetition, or other risks

Optimal job rotation includes the following:

- Ensuring tasks use different muscle groups

- Rotating frequently (depending on the tasks, a rotation every 30 to 120 minutes is ideal)

- Rotating tasks that have different production rates, force requirements, cycle times, and posture requirements

Although job rotation has a lot of benefits, it should not be the only strategy used to reduce injuries. Employers should continue to find ways to reduce exposure through automation and proper workstation set-up.

RSI DayPLUS 2018 webinar RSI DayPLUS 2018 webinar

Workplace Well-Being: Healthy Minds, Healthy Bodies

February 28, 2018

8:30 a.m. to 1:30 p.m. (EST)

Repetitive strain injuries (RSIs) involve damage to muscles, tendons, and nerves caused by overuse or misuse. RSIs affect more than 5 million Canadians and are also increasingly being reported by students.

To increase awareness about RSIs and how to prevent them, the Occupational Health Clinics for Ontario Workers (OHCOW) is offering a free webinar as part of 2018 RSI Day+.

For more information on these or other ergonomics topics:

|

Musculoskeletal injury (MSI) risk controls

Musculoskeletal injury (MSI) risk controls

RSI DayPLUS 2018 webinar

RSI DayPLUS 2018 webinar